Annual or monthly inspection of machinery and equipment of office is essential to create a maintenance report. The maintenance group inspects, services, and repairs the equipment used in an organization following a periodic timetable. Timely maintenance of the furniture and the office restricts things from getting more depreciated and helps retain their life.

Statistics say, more than 50% of existing organizations spend nearly 10% of their annual revenue behind maintenance. This study was done in the year 2020 in plant engineering. Unlike these organizations, several companies do not consider contributing their 10% of annual earnings behind the maintenance of the equipment alone. But the well-recognized companies that maintain the office appliances along with the transportation modes used need maintenance on a timely basis to function smoothly. They think it is worth investing behind the appliances rather than investing in purchasing new assets.

Table of Contents

What is a Maintenance Report Form?

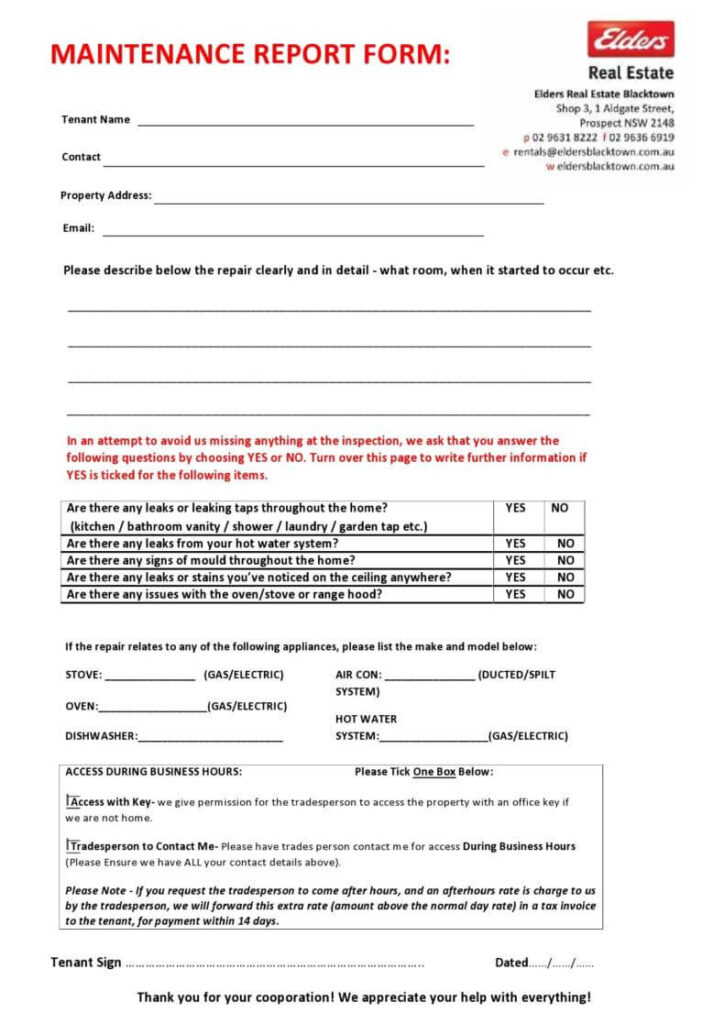

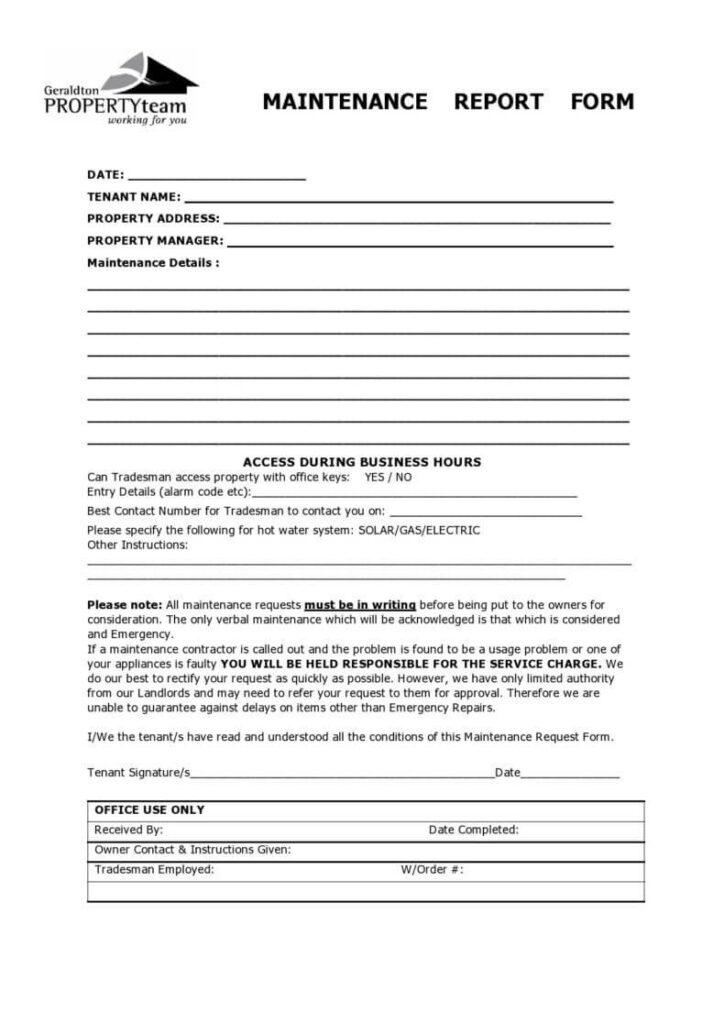

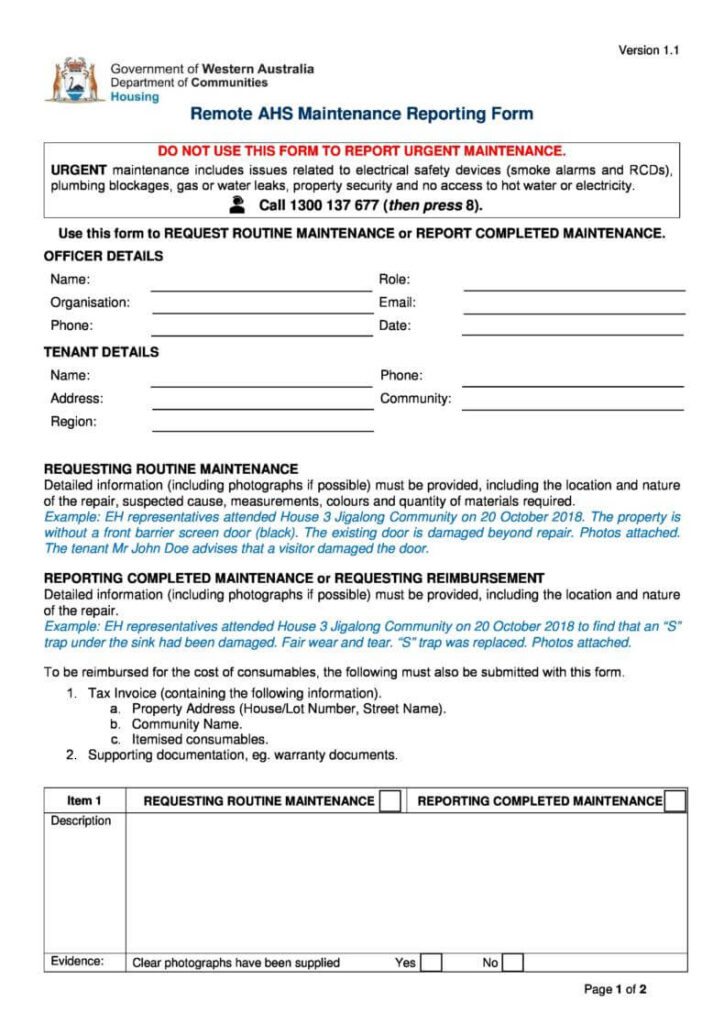

A maintenance report form is a document used in companies to inspect office equipment, and if found any issue, repair it. A complete record of the repairs and maintenance is taped in the maintenance service report.

Preserving the existing assets of the business is much more essential than investing in the purchase of new assets in consecutive years. This is why the maintenance report template is utilized so a business could have evidence of the changes/ maintenance done in the company machinery and other equipment.

Maintenance Report Forms

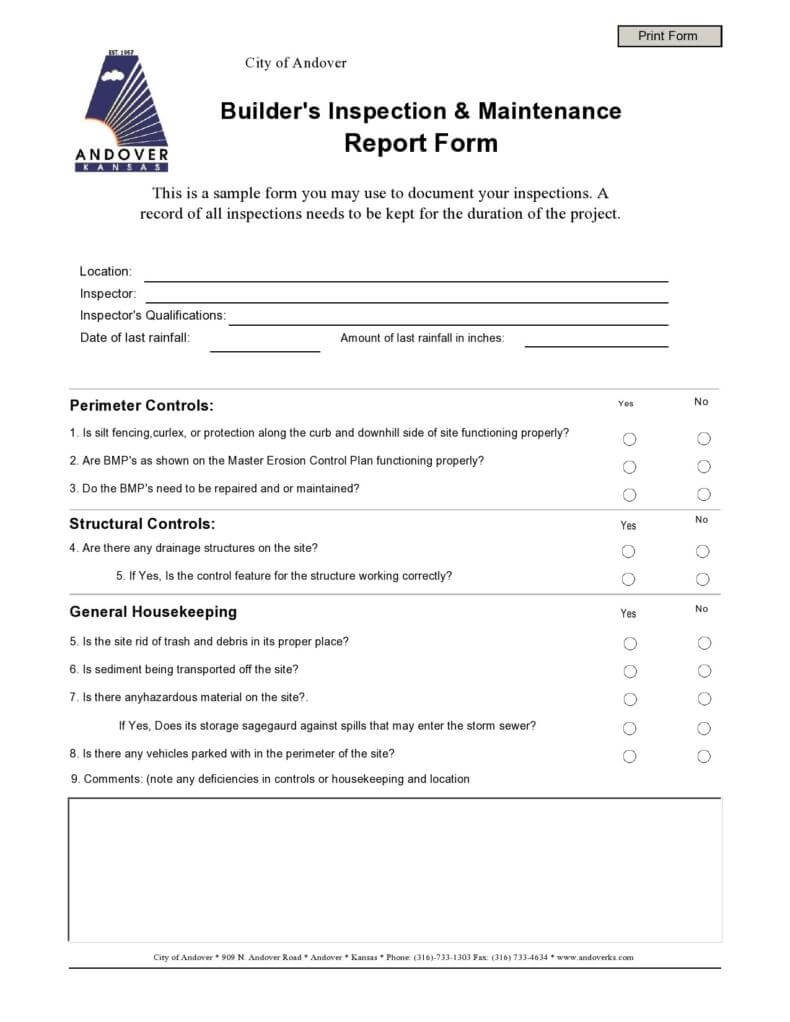

|

|

| Download | Download |

Maintenance Report Form Template

Maintenance Report Form Fillable Template |

Editable Maintenance Report Form Template |

|

|

| Download | Download |

What are the Works Involved in a Maintenance Report?

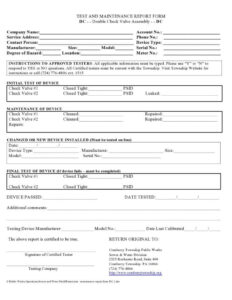

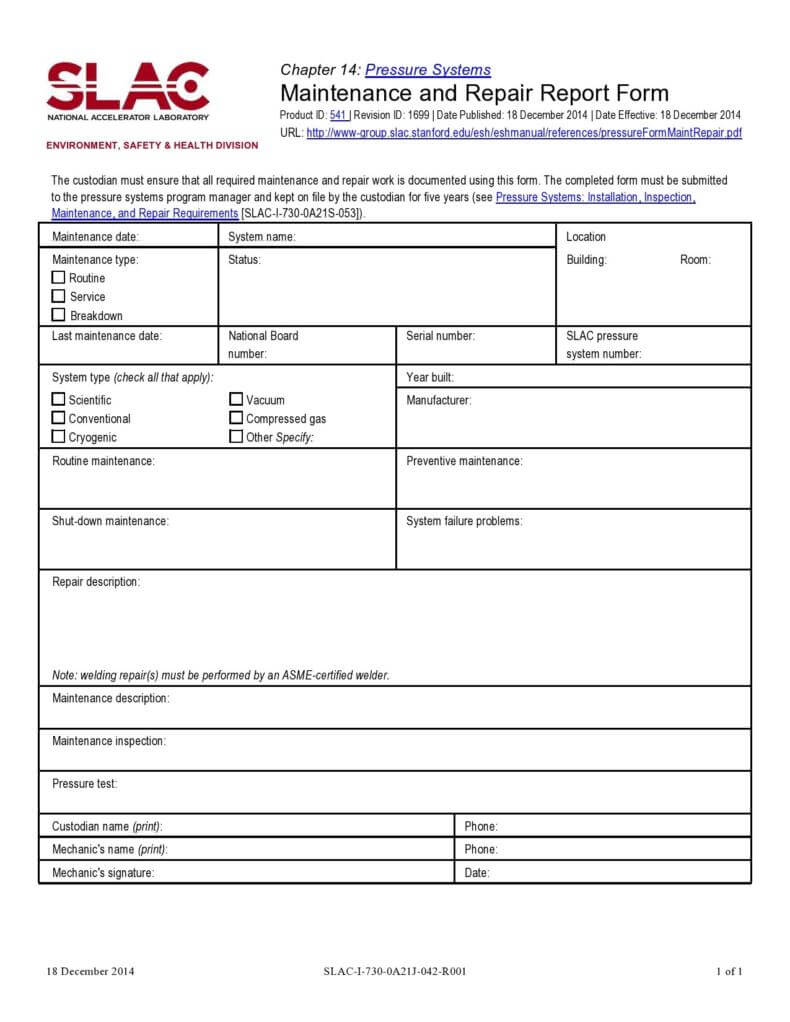

In the repair and maintenance report format, the elements that clearly defines the existing condition of the office equipment and furniture, show causes of the repair, present the initial test, shows the maintenance done, record the changes, and produces the final test of the device with some additional comment and the date are incorporated.

-

Knowing the Equipment.

A line down the name of the equipment and their usual properties like a serial number, device type, meter number, manufacturer, and the degree of hazard.

-

Encountering the Issues.

The next section of the maintenance report template includes the information that came out from the initial test of the device. The malfunction experienced and the problem encountered by the employees and the workers while utilizing it must be reported in the section.

It includes the check value, closed tight, and other bases of inspection.

-

Maintenance and repairs.

In the subsequent section of the editable maintenance report template, register the information of any repairs and maintenance and done to the listed equipment.

It registers the repairs done to the machine, type of maintenance done, cleaned or repaired, any exchange of devices.

-

Installing New device.

While maintaining the machines and inspecting them, the one who is responsible for repairing them might or find some of the internal or external devices of any equipment damaged and change the device with the new one. In such a case, the installation of a new device or change in any equipment parts is recorded.

It registers the date, type of device, name of the manufacturer, model number, serial number, size, and color of the device. Each of this information is important to record specific and accurate data.

-

Final test.

The accurate procedure of maintaining and repairing office equipment and company furniture is to conclude it with the final test. If there had been any installation of new devices or, just usual maintenance even then the equipment needs to be tested, so the issue is not pop up while operating it.

Register if the valve has been checked, PSID, and other necessary data.

-

Date tested.

Mention the date on which the repair and maintenance have been done and tested.

-

Giving Additional Comments.

If the repairer has any suggestions to provide or any additional comments to make on the operation done, then they could add in the specific column. Fewer times, the one who repairs the machinery suggests if it could be used to its highest capacity or it is needed to be reduced to 70% or 60% of its actual capacity.

Aside from them, if there are other essential components, you could add them in the section as well. It largely depends upon the advice and the requirement of the company, that the maintainers need to abide by.

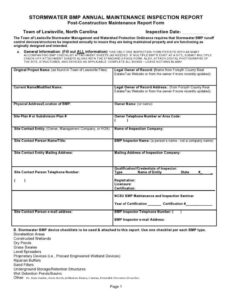

Regular Maintenance Reports Format |

Annual Maintenance Inspection Report Template |

|

|

| Download | Download |

College Inspection And Maintenance Report Form Template |

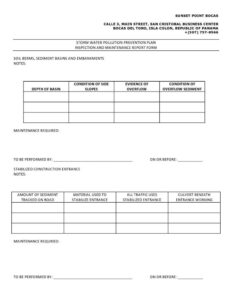

Storm Filter Inspection & Maintenance |

|

|

| Download | Download |

What is the Necessity of a Maintenance Report Form?

The maintenance report contains information on equipment inspection and its repairs. As we mentioned earlier, the companies spent 5 to 10% of their earnings behind these maintenance services. It is equally important as crafting the maintenance report form. You might be wondering about the benefits of a maintenance report form because of which organizations invest time behind it.

Periodic maintenance of company equipment and registering the same in the maintenance report form is essential as-

-

Increases the lifespan of the Assets.

The operating equipment needs to be available during work time and the proper maintenance of the assets of the organization helped increase the lifespan making it more reliable and durable. Therefore the companies taking proper care of the office equipment might spend a few amounts on its maintenance routine but save it from depreciating to a far extent.

-

Ensure employee safety.

Operational safety is the primary obligation the company must follow to ensure employee safety. Any malfunction in the equipment could lead to serious injury and accidents. Any operational glitch in the machine functioning will result in serious damage both to the company and to the employee, which will be hard to recover. Therefore regular checkups and proper maintenance of the company working asset is essential to prevent any unexpected risk.

-

Improves efficiency.

To perform the task in the desired capacity, the Machines need to be working in a stable condition as is expected. Regular maintenance and repairs add to the benefit of retaining the capacity and increasing efficiency. In this machine-driven work culture, labor productivity is only expected to increase if the machines work as is expected. It is only possible on pre- identification of defaults in the machine. Earlier notice of repair prevents any work malfunction and helps increase the efficiency of the machinery as well.

-

Minimizes cost.

The sudden requirement of money to purchase the required assets of the company could be prevented by maintaining the current equipment. The longevity of the company machinery helps the company from spending behind them.

Just the normal calculation explains the reason why it minimizes the cost. The price of a machinery is more than the cost incurred for it repaired. Due to its regular maintenance, the company does not need to invest in a new purchase; therefore, the cost minimizes.

-

Serves as an effective way of keeping track.

The expenditure in card behind repairing and maintaining the machinery and other equipment timely is to be recorded in the books of account. The auditors and the accountants need vouchers or evidence that prove the same. This is the time when the maintenance report form comes to use.

Anyways the maintenance report form and template serve as the convenient tool used to keep the records of the maintenance done. This particular document is also used by employers and repairs to know the history of the damages and repairs. Any requirement of replacement of the machinery parts is well determined if there is a history of the same.

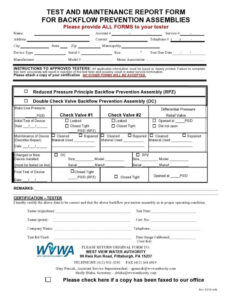

Sample Test And Maintenance Report Form Template |

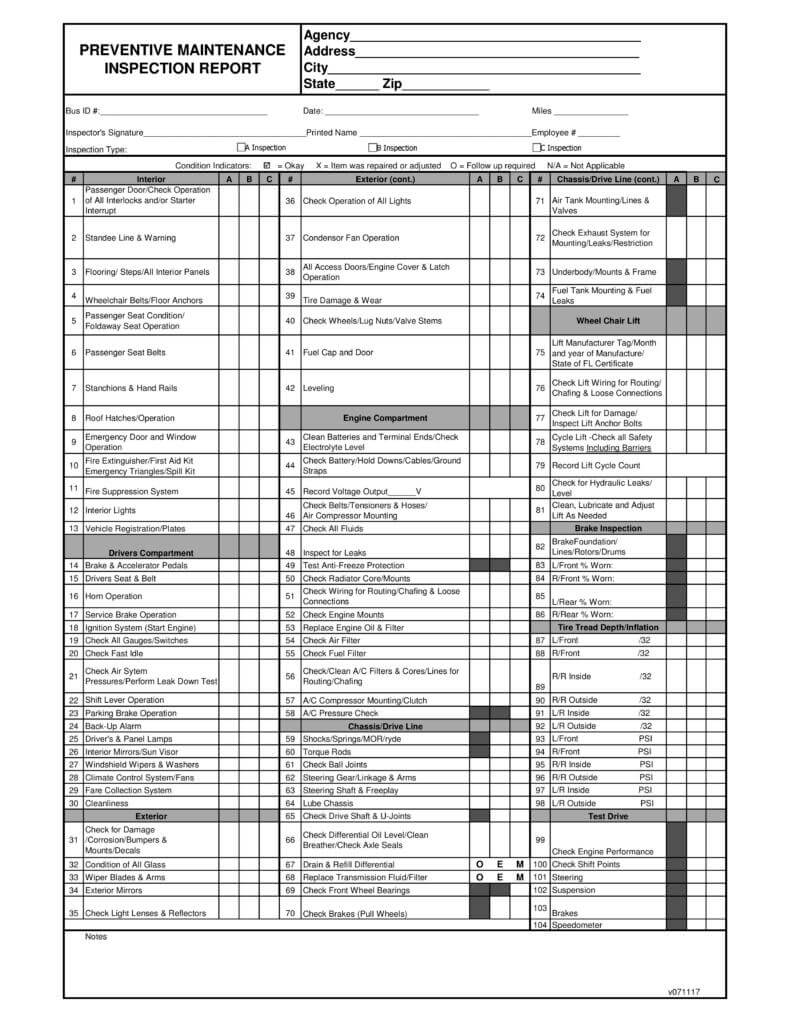

Preventive maintenance report format |

|

|

| Download | Download |

How to Build a Maintenance Report Form Professionally?

Creating a maintenance report form has some steps and guidelines. The individual creating the maintenance report form decide what to include in and what not to. Depending on its content, the maintenance report form will be used as a reference. Therefore one must learn how to create the maintenance report form effectively. You might create it as per your rule but any missing necessary element would not serve the purpose.

1. Plan the document.

The first step of creating the maintenance report form would be to prepare the document. You must have a clear vision of what you want in the maintenance report form. Consult with your seniors or your team members and outline the elements.

The prior preparation of the document makes the work easier and firm.

2. Craft the list of parts.

List down the name of machinery and its internal parts that need to be repaired. However, it is the work of the tester to identify those internal required devices that need to be altered or repaired. But if you already have those in the notice, listing them up in the document would help the tester to fasten the process.

3. List the defects.

The malfunction observed while operating the equipment must also be listed. The tester and the one who will repair would ask what the issue in the machine that notified them was. At such time you need to display and show them the reasons and the problems that crop up during its operation.

Different organizations have different perspectives but the best way of maintaining the maintenance report form is to list the defects as well. The corporation is needed to effectively repair the defaulted machine and identify its issue.

4. Line down the prospective suppliers and experts.

Along with the list of defects, the parts lining down the prospective suppliers’ names and the experts is essential. The company must have some options in hand in case any tester is not available in case of emergency, they could contact the other.

Being a recognized company, you might have some selective suppliers and experts in mind. List the name and the details of them in the document.

5. Jot down the elements.

All the advanced preparations needed to be done are completed and now it’s time to write down the necessary elements. Follow these steps to create it effectively.

a. Provide a title header at the top of the document.

b. Write the name of your company and contact details.

c. Write down the name of the manufacturer.

d. Also include the name of the selected tester for the period.

e. In the next section includes a paragraph of the introduction.

f. Mark the degree of hazard and device type.

g. State the results for the initial test of the device.

h. Write the maintenance status of the device.

i. Put information concerning any new device installed.

j. Register the results of the final test of the device.

k. If the final test fails, record the information.

l. Put a blank for the additional comments to be made by the tester.

m. Write the date on which the machinery was tested.

n. State the name of the testing device manufacturer, the model number.

o. State the name of the certified tester.

p. Signature of the certified tester.

q. Name of the company.

6. Proofread.

Last but not least step is to recheck the document before printing it. Before you print the document, make sure you get it approved by your employer.

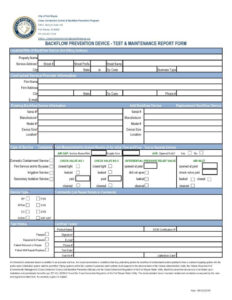

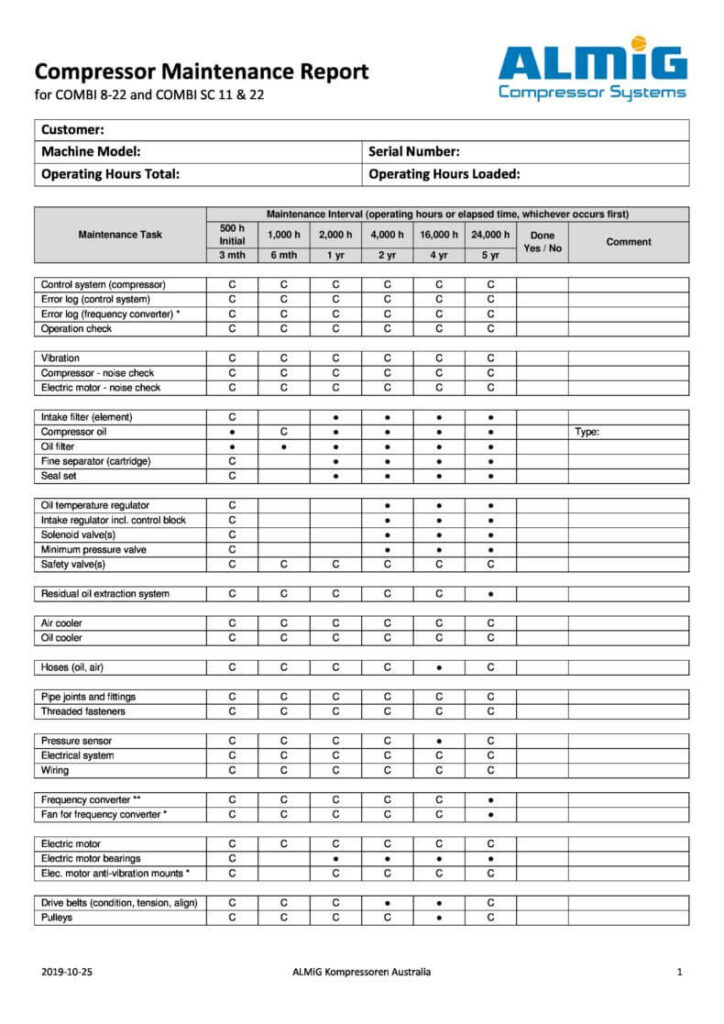

Daily maintenance report format |

Machine maintenance report format |

|

|

| Download | Download |

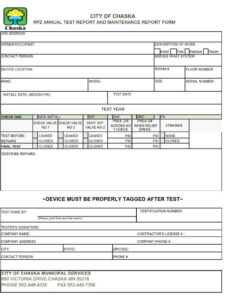

Preventive maintenance report sample |

Equipment maintenance report template |

|

|

| Download | Download |

Maintenance Repair Report Templates

Maintenance monthly report sample |

Foot Trail Maintenance Report Form Template |

|

|

| Download | Download |

Process of Scrutinizing Maintenance Report form

The Maintenance Report form is a document that is filled out by the mechanic detailing the work that was completed. You should identify problem equipment regularly using a maintenance or work order template and they are quite capable of lending a hand scrutinizing. Once completed, you would have a proper idea of which needs to be fixed. Here are the practical steps one can follow to Scrutinizing Maintenance Report:

- Analyzing the Maintenance Report:

The first step in analyzing the Maintenance Report form is to look at what kind of items were checked off, on the form. If there are items that are not checked off then there may be an issue with the vehicle’s maintenance schedule or with how well it is being maintained. -

The next step would be to look at when the work was done and compare it to when it should have been done according to the maintenance schedule.

-

Analyze the duration of equipment downtime:

The utilization of time is critical when it comes to the use of equipment. Equipment downtime means lost revenue and increased costs in repairs. In order to better understand the downtime for equipment in a given year, we would need data that has been organized by month. In this analysis, we will be taking a look at the past year’s of data and then entering them into a graph. -

Check the history of maintenance work requests and complaints

Have you ever thought of checking maintenance work history? Review the reported work requests and complaints for the previous year. Analyze the assets that registered many requests or complaints associated with maintenance work. - Next, you would want to do is look at the cost of each item and compare them. Once everything’s done, you would have the proper knowledge of what should be done in terms of maintenance activity to be back on the optimal production point.

Sewage Tank Maintenance Reporting Template |

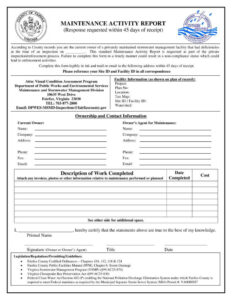

Maintenance Activity Report Template |

|

|

| Download | Download |

Once you have the proper understanding of the reasons why machines are failing, you can obtain preventive maintenance schedules. There could be a number of reasons why a machine is repeatedly failing:

- At the verge of Life span end:

This is one of the primary causes of machines failing frequently. When the machines approach its life span working duration, it is quite natural that they would perform less and will have breakdown frequently due to performance depreciation. -

Lack of Proper maintenance procedure:

Proper Maintenace procedure is extremely critical and companies should pay great attention to that to have a better machine working life span. Here are a couple of This one should keep in mind for Equipment maintenance:

– Maintain Equipment regularly

– Take care of high quality supplies or spare parts.

-Unfortunately, our maintenance technicians are not trained well enough to do their jobs right.

Here are a couple of points you can check to handle this issue:

Review and maintenance report form carefully and try to pin point the root cause. Perform preventive maintenance schedules according to the situation.

Equipment fault report template |

Schedule Maintenance Report Template |

|

|

| Download | Download |

If you have any DMCA issues on this post, please contact us!